What is electrical safety?

Electrical safety is a system of general and technical solutions to avoid or minimize the exposure to workers and employees working with and around electrically charged equipment, appliances, and tools from injuries and ill-health effects associated with electricity.

It is a set of instructions to reduce hazards and prevent their threatening effects for the exposed and the general public (including employees and visitors) in case of an incident.

Various electrical hazards are

Unprotected live wire

Use of damaged tools and equipment

Faulty wiring

Exposed electric parts

Improper or no use of PPE

Contact of exposed cable with water or wet surfaces

Overhead power lines

Contact with underground cables and equipment

Overburdening or overheating of circuits

Combustible/flammable substances

Inefficient or no grounding/earthing

Incorrect handling of equipment, tools, and appliances

Poor laying and cable-pulling practices

Slip, trip, and fall

Importance of electrical safety at the workplace

Electricity is immensely forceful and quite harmful if not handled properly. It can lead to major accidents and can also lead to dangerous fatalities.

Working around electricity can be quite dangerous if the workers fail to identify and control hazards timely.

The voltage of electricity from electrical equipment and tools in a workplace can severely injure or even kill a person.

As per the 2020 Accidental Deaths and Suicides in India (ADSI) report,

15,258 people died from electrical shocks and fires.

CEA reports 7,717 fatal human accidents in FY19-20.

(source: moneylife)

Electrocution is the 4th most common cause of death in the workplace, responsible for a large majority of disabling injuries which can cost companies millions in medical costs.

To keep electrical workers safe at work, industrial electrical safety training is one of the most desired way to communicate all the essential skills and techniques required for the job.

Near miss accidents are quite common in electricity-related jobs and can be taught through safety animation videos easily.

Risks

Electric burns and shocks

Electrocution

Fire

Explosions leading to loss of resources and assets

Precautions

1. Use of electrical safety devices:

Install RCDs, MCBs, ELCBs, etc. based on the requirement to monitor the flow of current and quickly disconnect power in the event of a fault, reducing the risk of electric shock.

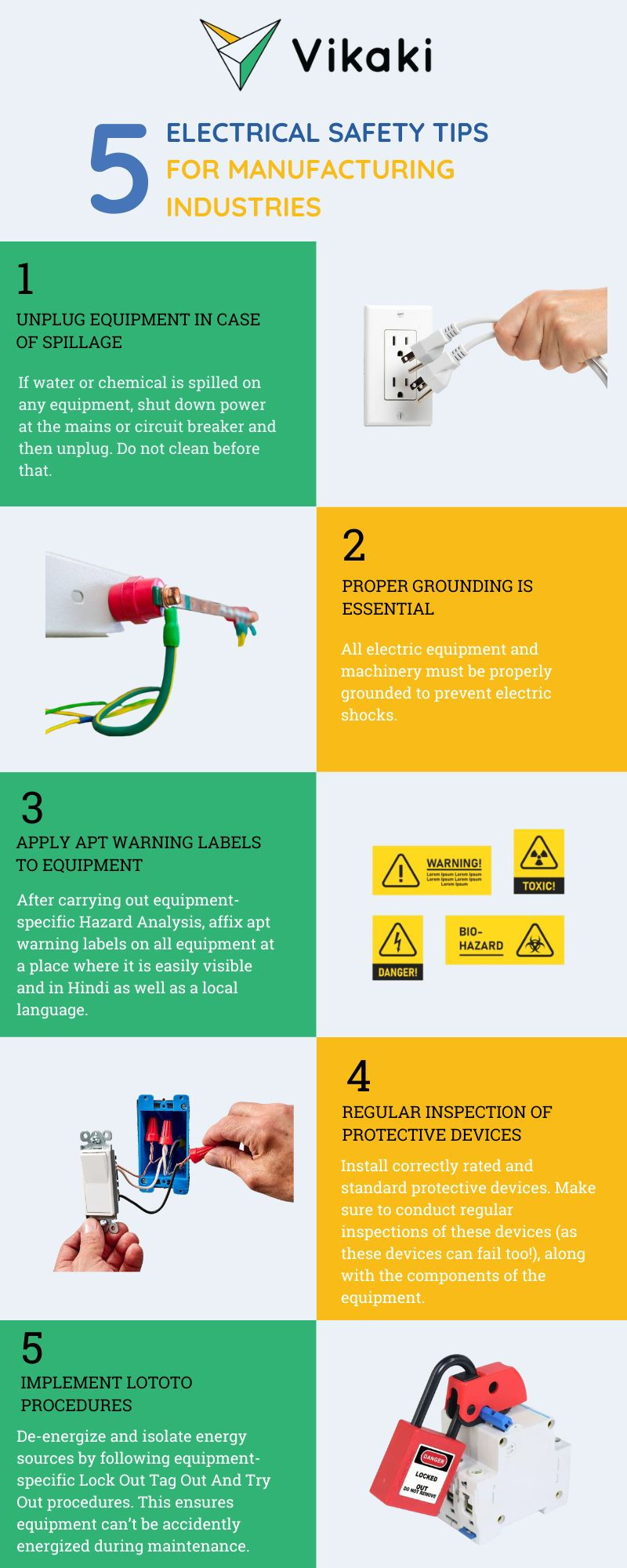

2. Proper implementation of LOTO during maintenance:

Develop and maintain detailed lockout/tagout procedures for each equipment. Clearly label and document each energy isolation point to facilitate safe shutdowns. Ensure that only authorized personnel have access to the locks and keys, and that tags are clearly visible. Ensure that the LOTO procedure is followed diligently as per the SOPs.

3. Avoid combustible/ flammable material:

Don't use combustible/ flammable materials near high-voltage equipment.

4. Provide electrical safety training:

Employees should be given electrical safety training so that they are well qualified and knowledgeable to do their work properly. Safety animation videos can be developed to give details about Do’s And Don'ts for electrical safety.

Electrical safety is crucial not only in the workplace but also within households.

5. Caution:

Always stay alert while using electrical equipment. Safety induction training can help newly joined employees with the basic safety procedures to follow on the job.

6. Examine electrical current:

Before working with wire/ cable or any metal surface associated with electricity, check the electric current using a multimeter.

7. Secure electrical cords:

Laying or hanging electric cords can result in falling, hurting, and tripping hazards. Use proper tape extension cords at the work site to prevent these hazards.

8. Regularly inspect electrical equipment, connections and cords:

Check the electrical equipment, connection and cords like plugs and outlets for any wear and damage signs. Immediately change the faulty materials to avoid accidents.

Ensuring electrical safety in manufacturing is crucial for the well-being of your workforce and the success of your business.

9. Wear personal protective equipment (PPE):

Hard hats, safety glasses, and insulated gloves should be worn at all times when using any electrical devices. Job specific safety training can provide the necessary electrical safety guidelines.

It is the employers' responsibility to provide workers with the best electrical safety training in the workplace, as it enables the workers to make educated decisions while working with/around electricity. An electrical safety training program is a recommended way to mitigate the unpredicted accident/ incident-related costs for your business.

Comments